Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

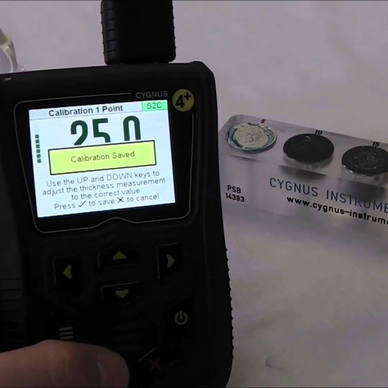

Ultrasonic inspection uses a piezoelectrictransducer connected to a flaw detector, which in its most basic form is a pulser-receiver and oscilloscope display. The transducer is passed over the object being inspected, which is typically coupled to the test object by gel, oil or water.

A thickness gauge is an essential quality assurance tool when anodizing, galvanizing and applying zinc coating to metallic surfaces.

.

Liquid penetrant (LPI) and magnetic particle (MPI) inspection techniques are methods that supplement visual inspection, revealing defects such as fine cracks or micro-porosity that would be invisible or difficult to detect by the naked eye.

We love our customers, so feel free to visit during normal business hours.

Open today | 09:00 am – 05:00 pm |

Copyright © 2024 We Brands Group - All Rights Reserved.

Powered by Maroselli

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.